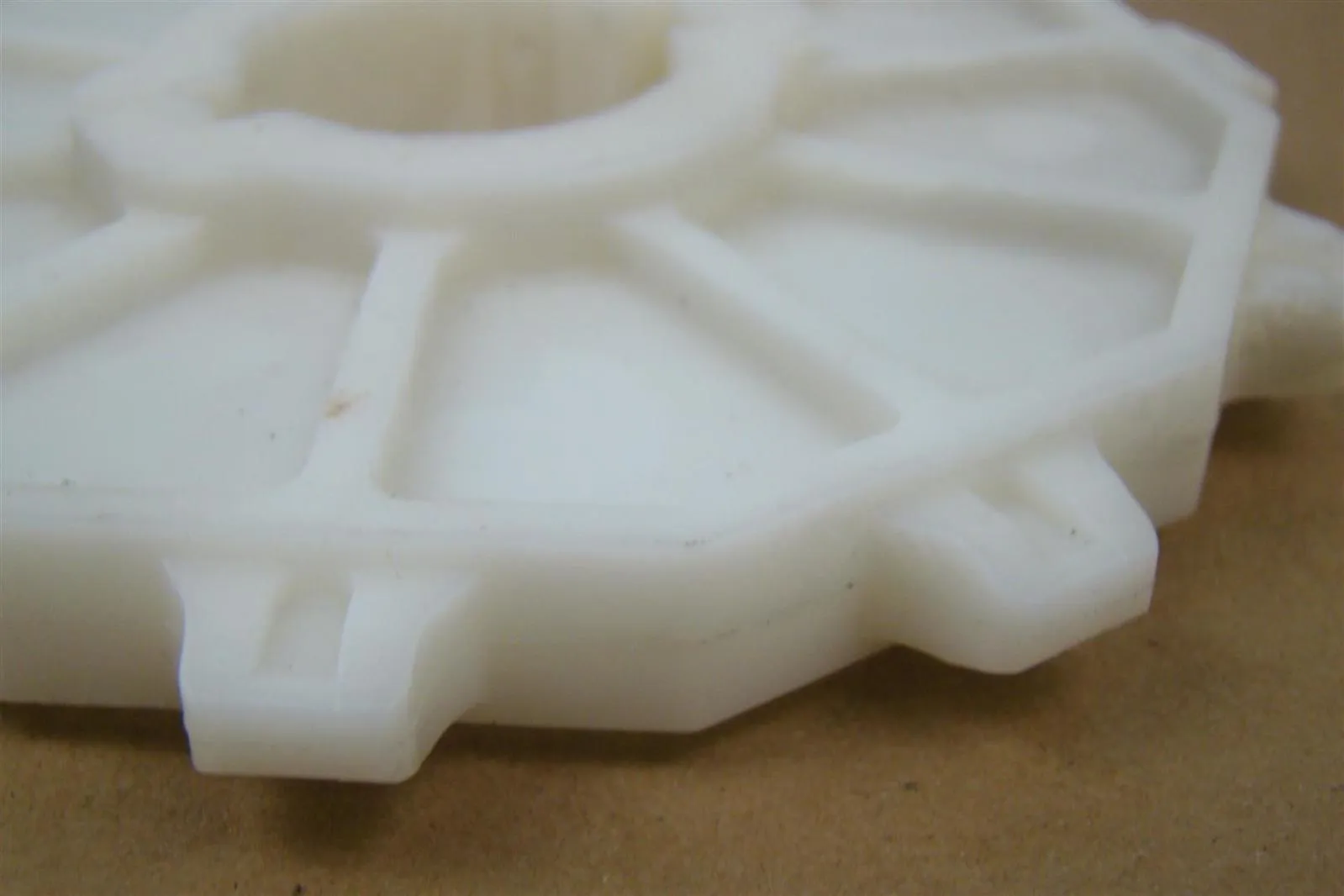

Plastic Sprocket

A sprocket is a simple mechanical wheel with teeth or small grooves designed to rotate and engage a link in a chain or belt. However, in order to be compatible, they all need to be of the same thickness and spacing.

Plastic sprockets run more quietly and cause less chain wear than metal sprockets. Other benefits include corrosion resistance, light weight, strong impact resistance, and FDA-approved materials.

ADVANTAGE

PLASTIC SPROCKET ADVANTAGES

Resists fungal and bacterial growth

Corrosion, chemical, wear and moisture resistant

Self Lubricating

The compressibility of plastic materials results in greater tooth deflection than metal sprockets. The greater tooth deflection means that several teeth will carry the load of the chain, increasing the sprocket’s total load capacity to about the entire working load of the chain.

Applications of Plastic Sprockets

Applications for plastic sprockets include dusty or gritty environments, food applications requiring frequent wash-downs, and areas where a quieter chain drive is needed.

Sprocket & Gear Arrangement

We can make several types of engineered plastic sprockets:

Wire Belt | Roller Chain | Wastewater | Mill

Considerations

Chain Type | Set Screws | Number of Teeth | Hub Type

Bore Type & Size | Split or One-Piece | Key Way | Hub Diameter

Nominal Width | Outside Diameter | Length Through Bore (LTB)

Pitch and Pitch Diameter

WHY CHOOSE THE PLASTIC SPROCKET

Plastics combine the strength of steel with the lightness of aluminum. Plastic sprockets are lightweight, easy to clean, durable, and provide excellent wear resistance. This provides food handling equipment manufacturers with reliable and common components for a variety of food preparation and transportation systems.

Our Plastic Sprocket

The plastic sprocket made of these durable polymer materials has the advantages of wear resistance and noise reduction compared with similar metal products.

PLASTIC SPROCKET

- Self-lubricating grade, negating the need for additional lubricants.

- Lower coefficient of friction and increased wear resistance compared to metal parts.

PLASTIC SPROCKET

- Good corrosion resistance.

- High impact strength.

PLASTIC SPROCKET

- Lighter weight than metal parts.

- Reduced noise levels during operation than metal parts.

types

The Different Types Of Sprockets

- Double duty – These have two teeth per pitch – so that when one set is worn down the links can be advanced to a new set of teeth.

- Hunting tooth – These have an uneven number of teeth, meaning they tend to last longer than other types because every time it turns, the links engage a new set of teeth. This means each tooth makes contact only half as many times as other types of sprocket, helping it last longer.

- Multiple strand – This type is used where more torque and power is needed or if two or more items are being powered by the same drive shaft.

- Quick disconnect (QD) – These tend to be used with higher working loads, and some feature a reverse mounting function.

- Idler – These are used where long lengths of chain can slack, to help avoid whipping, or where it’s been guided around an obstruction. It also helps prevent uneven load distribution.

Shop Online

High QUALITY PLASTIC SPROCKET

What is the Function of a Sprocket?

Essentially, a sprocket is a gear that fits into a drive shaft. As it spins, the teeth lock on the chain, causing it to pull. The wheels of a sprocket can be made of metal or reinforced plastic.

There are different types of sprockets, each with a different function. For example, a bicycle has two sprockets connected by a chain. These sprockets carry the rider’s weight and transmit the bike’s spin to the wheels.

WHY CHOOSE US

We are one of the best plastic sprocket manufacturers.We can offer a wide variety of plastic sprocket designs and different plastic sprocket sizes.We also can provide some plastic sprocket diagram.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!